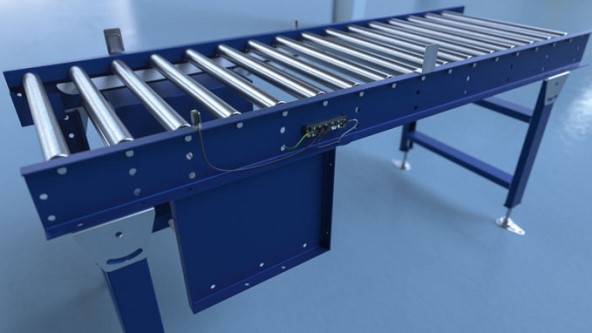

I/O Blocks Control Roller Conveyor Modules

Decentralized control of conveyor system modules avoids long cycle times, makes commissioning faster and reduces wiring costs

In automatic conveyor system modules within a logistics system, roller conveyors transport containers or transport boxes. Optical sensors trigger and stop the motors in the roller conveyor. Other modules are used as switches, turntables or stoppers.

Your Benefits

- Offline tests make commissioning faster

- Low wiring costs and smaller PLCs reduce the overall cost

- Controller in the I/O module shortens response times

Solution for Problems Caused By Long Cycle Times

Centrally controlled plants in which a PLC issues the control commands for the entire plant are often subject to long cycle times even with high-performance controllers — especially when networks comprise many nodes, as is often the case in intralogistics systems. If this results in the PLC reacting too late, the containers can become congested or be controlled incorrectly. These errors require manual intervention in the plant, but could be avoided by implementing decentralized solutions.

Decentralized Control with Fast Response Times

I/O modules with integrated logic control conveyor system modules independently. Actuators and sensors are connected directly in the field to the IP67 I/O block. With a response time of 2 milliseconds, the decentralized solution in large plants works much faster than centralized controllers. The conveyer speed can therefore be increased if necessary, which in turn increases the performance of the entire plant. Signal lights can also be activated quickly and easily on site. The logic control function is integrated free of charge in all Turck block I/O modules (IP20 or IP67).

ARGEE Intuitive Programming Interface

The modules are programmed directly by the programming interface ARGEE on the integrated web browser. A flowchart view allows the modules to be programmed without the need to write program code. Established and tested programs can be easily transferred to other modules of the same type.

Module Tests without Controller Speed Up Commissioning

The decentralized controller allows conveyor system modules to be fully tested in the factory. This speeds up commissioning for the end customer and eliminates time-consuming troubleshooting during installation and commissioning.

I/O Hubs Reduce Wiring Costs

The user can access all logic control functions on all block I/O modules free of charge. This also includes the TBEN-S and TBEN-L series I/O-Link masters. This allows the wiring for the simple switching signals to be routed through I/O-Link junction boxes. IO-Link devices are connected to the master via these I/O hubs, allowing up to 16 switching signals to be connected via a single IO-Link port. This massively reduces the cost of wiring. In this application, the decentralized components process the large amount of data to identify relevant information that is communicated to the controller, thus reducing the amount of communication to the controller. The bottom line is that choosing a less powerful PLC also reduces costs. The lack of protective housing on the module also saves installation costs, since the IP67 blocks are mounted directly on the roller conveyors.

- Automotivo

- Detecção de veículos na Produção Automobilística

- Reliable Skid Detection in Automotive Production

- Error-free JIS Order Picking for Bumpers

- RFID Bus Mode Ensures Quality of Lithium-Ion Batteries

- Level Measurement in Dip Coating Line

- Level Control in Central Lubrication System

- Quality Assurance on the Gluing Robot

- Tilt angle sensor accelerates platform alignment

- Controle e Monitoramento de condições em Motores

- Sinais de segurança dos processos do módulo IP67 híbrido

- Monitoramento descentralizado de estações de refrigeração com RFID

- Células robóticas para solda em Rede Ethernet

- Monitorando o circuito de resfriamento em equipamentos de soldagem

- Flow monitoring in drum washers

- Monitoramento de Condição de Motores como Retrofit

- Monitoramento do lubrificante de refrigeração em CNC

- Prensas de metal com identificação da ferramenta

- Detecção de porcas de solda

- Identificação de Skid

- Montagem Final

- Verificação sem contato para pallets transportadores

- Detecção de nível de itens com RFID UHF

- Monitoramento do lubrificante de refrigeração em máquinas

- Controle de pressão hidráulica em prensas

- Medição da pressão de processo nos elevadores

- Cases de sucesso

- Laser Sensor Detects Black Bumpers in Assembly Cell

- Tecnologia de segurança descentralizada para produção modular

- Sistema de transporte modular

- RFID e Módulos I/O para mudanças seguras na ferramenta

- Guias RFID para AGV em produção de suspensão

- IO-Link na produção de Escapamentos

- Identificação do carregador da peça na produção de Ventilação Traseira para BMW

- Detecção de porca para solda

- Rastreabilidade RFID

- RFID na produção de motores

- Produção de Para-choques com Identificação

- Soluções para Linhas de Pintura

- Sensores de Soldagem e Montagem

- Sensores de Ângulo para sistemas de montagem

- Identificação de Ferramenta

- Identificação RFID em Bicos Injetores

- RFID em montagem de carrocerias

- IO-Link facilita a produção de engrenagens de transmissão

- Química

- Decentralized Automation in Ex Areas

- RFID Control of Tube Connections in the Ex Area

- Ethernet para economizar espaço na Sala de Instrumentação e Controle

- Automação baseada em Ethernet para Skids Modulares em Áreas Ex

- Interface Ex em plantas de processos modulares

- Detecção de Pigs

- Sinal Remoto de I/O

- Fácil conexão com dispositivos de campo

- Processamento de Sinais com Sistema I/O no Painel de Controle

- Separação de sinal com tecnologia de interface no painel de controle

- Identificação de Conexões de Mangueira

- Monitoramento Eficiente de Condições de Painéis

- Monitoramento de abertura de válvulas com atuadores

- Planejamento e Montagem de Soluções de Sistema

- Cases de Sucesso

- Sistema I/O Excom cria espaço em salas de I&C

- RFID para Zona 2 e 22

- Controle de Testes Eficiente

- Comunicação de campo intrinsecamente segura

- Parceria para Sistema de controle de Processo

- I/O Remoto para área classificada

- Sensoriamento da Posição de Válvulas

- Flexibilidade com Fieldbus

- Gestão de Ativos com I/O Remoto

- Posicionamento correto com RFID na produção de carboneto

- Conversão rápida em espaço restrito

- Energia

- Bebidas e Alimentos

- Sensor de monitoramento de condição automatiza o controle climático

- Monitoramento de Condições em Painéis de Controle

- Monitoramento de Condição em Armazéns

- Controle de espessuras de massas em Máquinas de Enrolamentos

- Identificação de recipientes para alimentos

- Verificando Recipientes

- Detector de posição de válvula

- Detecção em Tubos Angulares

- Identificação de moldes de chocolate

- Cases de Sucesso

- Grist for the Mill

- Decentralized Control Modules in Coldstore

- Rastreamento com RFID na produção de carne

- Encoder sem contato no processamento de batatas

- UHF RFID no Centro de Distribuição de Alimentos

- RFID para produção de chocolate

- I/O Distribuído para Equipamentos Alimentícios

- I/O Remota para Destilaria

- RFID e Autoclaves

- Transparência na fabricação do chocolate

- Fontes de alimentação IP67 para transportadores

- Identificação no Armazenamento de Produtos Alimentícios

- Logística

- Tracking Big Bags with RFID

- Distance Detection in Container Cranes

- Access Control for Protected Areas

- Muting descentralizado de equipamentos de proteção eletro sensíveis

- I/O Blocks Control Roller Conveyor Modules

- Detecção Rápida de tags nos Portões do Armazém

- Item-level Detection with UHF RFID

- Manutenção preventiva em correias transportadoras

- Detection of Transport Containers

- Level Detection in Vessels

- Identificação de Recipientes (Cryovessels)

- Identificação de recipientes móveis com dispositivos portáteis

- Identification of Food Containers

- Identificação de para-choques just-in-sequence (JIS)

- Condition Monitoring in Storage Rooms

- Collision Protection on Reach Stackers

- Cases de Sucesso

- Shipment Tracking for Raw Materials

- RFID-Based Tracking Solution for Loading Error Minimization

- RFID-based Tracking of Inbound and Outbound Materials

- Decentralised UHF RFID Solution

- Contact-free Encoder in Potato Production

- Decentralized Control Modules in Coldstore

- Controle de Velocidade com Sensor Radar QT50

- Fontes de Alimentação IP67 para Transportadores

- Modular Conveyor System

- Solução RFID para armazéns e centros de distribuição

- AGV guiado por RFID na produção de suspensões

- Identificação de Fármacos por RFID

- UHF RFID in Food Distribution Center

- Mobile Equipment

- Condition Monitoring Sensor Automates Climate Control

- Sensores ultrassônicos para compensação automática de inclinação

- Linhas de Distribuição para Pulverizadores de Campo

- Medição do ângulo em um pulverizador de campo

- Determinando a posição angular do guindaste

- Medição de inclinação de dois eixos em uma colheitadeira

- Proteção contra colisão em empilhadeiras de alcance

- Cases de Sucesso

- Safe Remote Maintenance of Irrigation and Drainage Pumps

- Access Control with RFID System

- Colheita Seletiva de Aspargo com Robô Autônomo

- Medição de posição com RFID e encoder

- Controlador de velocidade via Radar Sensor QT50

- Guias RFID AGV em suspensão de produção

- Módulos de I/O em super iate

- Encoder sem contato em navios draga

- I/O para sistema de aspersão

- Cabine de resfriamento

- Conectividade de Rápida Desconexão

- Soluções de Automação para frio Extremo

- I/O Remoto para Guindastes

- Pontes rolantes com sistema de elevação a vácuo

- Posicionamento na montanha-russa

- Soluções para máquinas móveis

- Posicionamento exato de altura

- Detecção crítica de ângulo

- Sensor de ângulo detecta a elevação de plataforma

- Óleo & Gás

- Embalagem

- Verificação descentralizada de embalagens por RFID

- Identificação de Cartuchos de Impressão Coloridos

- Operação Confiável das Máquinas

- Verificação de Recipientes

- Monitoramento de Tampas em Garrafas

- Monitoramento de Configurações em Processos

- Identificação de Garrafas Teste

- Monitoramento de Nível de Café Moído

- Detecção de Nível em Recipientes

- Detecção de caixas transportadoras

- Cases de Sucesso

- Farmacêutico

- End-to-End Sample Tracking with RFID

- RFID Control of Tube Connections in the Ex Area

- Verificação descentralizada de embalagens por RFID

- Automate Modular Skids

- Pharmaceutical Skids with Decentralized I/O Technology

- Ex Isolation in Modular Process Plants

- Control of Valve Interfaces

- Monitoramento de Atuadores de um quarto de volta

- Identificação de Tanques Portáteis

- Sinal Remoto I/O

- Planejamento e Construção de Super Skids

- Fácil Conexão de Dispositivos de Campo

- Identificação de botijões criogênicos

- Identificação de contêineres móveis

- Identificação de contêineres móveis com dispositivos portáteis

- Identificação de conexões de mangueira para precursores

- Identificação de conexões de mangueira em áreas estéreis

- Identificação de Conexões de Mangueira na Zona Ex 1

- Identificação de sacos e birreatores

- Identificação de Aplicações de Uso Único

- Cases de Sucesso

- Transferência sem contato de energia e sinais de comutação

- Misturador Industrial Controlado por IHM

- Controle de máquina de processamento de imagem com BL20 Codesys Gateway

- RFID para Identificação de Produtos Farmacêuticos

- Speed measurement of mixing heads in magnetic stirrers

- Reading Device Detects Different Materials

- Semicondutor

Select Country

Turck worldwide

-turck-image.jpg)

-turck-thumbnail.jpg)